What Is Hydro Flask Made Of and How Are Hydro Flasks Made?

This article will introduce some details about Hydro Flask, for example, What Is Hydro Flask Made Of and How Are Hydro Flasks Made?

Last Updated on March 11, 2024 by Tina ShaoHydro Flasks are some of the market’s most popular insulated water bottles. They’re loved by campers, hikers, and athletes alike because they keep your drinks hot or cold throughout your trip.

But what is a Hydro Flask made of? How are they made? Let’s take a look!

What Is Hydro Flask Made Of?

Hydro Flask is made from double-walled, stainless steel construction. It’s durable (and heavy) and will last you for many years. And for different parts, Hydro Flask uses other materials.

- Main Bottle Body: Stainless Steel SUS 304 (18-8): The outside of the bottle is made from high-grade Stainless Steel SUS 304 (18-8). Stainless Steel SUS 304 (18-8) – This alloy contains 18% chromium, 8% nickel, and 0.5% carbon. It also has very high corrosion resistance, making it perfect for use in various conditions with moisture exposure.

- The Bottle Lid/Cap: BPA-free Plastic: The cap on top of the bottle is made from BPA-free plastic instead of metal, so you can quickly drink from your Hydro Flask without burning your mouth on a hot or cold drink! This plastic can withstand high temperatures without degrading or melting, as other plastics do under similar conditions!

- Seal Gasket: Solid Silicone: The Hydro Flask Seal Gasket is made from solid silicone optimized for its performance and durability. This material provides an airtight seal between the lid and the bottle, so it’s perfect for keeping your liquids hot or cold longer than other options.

- Flex Boot: Premium Silicone: It’s premium silicone that protects against scratches and dents on your bottle if you drop it on the ground! This flexible rubber also gives each bottle an ergonomic feel, so it’s easier to grip when holding it in your hands while drinking from it, too!

How Are Hydro Flasks Made?

Hydro Flask water bottles are made using various manufacturing processes. The first step in making a Hydro Flask bottle is to create the outer and inner bottles separately.

Step 1: Manufacture outer and inner bottles:

- The first step is manufacturing the outer bottle, which starts with pipe cutting.

- Next, there is an expansion process where a small part of the inner bottle is inserted into an opening in the outer bottle and then baked in an oven at high temperatures to test its durability.

- The third step is separating and shaping, where workers check on various production parts to ensure they match specifications.

- Once this step has been completed successfully, necking occurs next, where workers begin rolling threads onto each end of both bottles. This ensures you can screw off either end easily without struggling or getting hurt!

Manufacture Inner Bottle: Cut raw material – stainless steel pipe – to the appropriate length and then drill the proper holes. The raw material is then welded together to form the inner bottle.

Step 2: Assembly

- Bottle Mouth Matching: Assembly both outer and inner bottle parts to make an empty but finished product ready to fill with liquid goodness! The inner bottle is placed inside a mold, allowing it to be heated and then cooled at the correct rates to take on its final shape.

- Bottle Bottom Assembly: Assemble the Bottom of the bottle by pressing the machine.

- Bottle Mouth Welding: Weld the inner bottle and outer bottle together to prepare for vacuum insulation.

- Bottle Bottom Welding: Weld the outer bottle and the bottle bottom to prepare for vacuum insulation

Step 3: Heat treating

Next, the bottles undergo heat treatment processes that strengthen and harden them to be ready for sale. These treatments ensure that each bottle can withstand extreme temperatures without breaking or deforming under pressure (like when drinking water out of one at 100 degrees Fahrenheit outside).

Step 4: Leaking test

This is a crucial step in the manufacturing process. The machine will test each bottle to make sure it doesn’t leak. This is done by filling your new Hydro Flask with water and then using the vacuum machine to test how much air gets into the bottle when you turn it upside down.

If there’s too much air, then there isn’t enough vacuum pressure inside your bottle, and it won’t keep your hot or cold drinks warm or cool enough for you!

Step 5: Vacuuming:

Vacuuming involves removing air from the bottle so it can be formed into its final shape. This removes any remaining air from the bottle, making it lighter and easier to handle. The process is done with a vacuum machine that sucks out all of the air in between two Stainless Steel walls

Step 6: Temperature Test / Insulation Test

After finishing the vacuum process, we ran another “temperature testing” test on each bottle before shipping them out. This way, we can ensure that our customers receive a product that will keep their hot beverages hot for up to 12 hours (or cold beverages for up to 24 hours).

Step 7: Electrolysis Polishing

The next step in the manufacturing process is electrolysis polishing. The material used to create your Hydro Flask water bottle has a particular texture and feel, which can be described as “rougher” than other materials.

Electrolysis polishing smooths out this texture and gives the bottle its final shape. After electrolysis polishing, your stainless steel water bottle will have less of a rough feel than before—this is why it feels so smooth when you hold one in your hand!

Step 8: Mechanical Polishing

Next up is mechanical polishing. Mechanical polishing involves using a buffer wheel that spins against another equipment part called an abrasive wheel. As these two wheels rub together, they buff away at any inconsistencies on your stainless steel bottle until everything looks even and perfect!

Step 9: Cleaning

Seriously – cleaning ensures every inch of your Hydro Flask meets FDA requirements by guaranteeing no harmful chemicals or toxins contaminate drinks stored inside it during use.

Step 10: External coating

The next step in the manufacturing process is adding an external coating to the bottle. In which the bottles get their primary color and texture. This can be done by powder coating or silk screening. Powder coating involves applying powdered paint, while silk screening involves transferring ink onto a surface through an open mesh screen with a squeegee.

This includes surface decorating, which can be painted or printed on by various methods, including powder coating, spray painting, silk-screening, and UV coating.

Step 11: Pattern and Logo Printing

The next step in the manufacturing process is pattern and logo printing. Your Hydro Flask and personalization bottles will be imprinted with a unique design at this stage.

Hydro Flask also offers custom patterns and logos for your bottle’s side panels so that you can make it yours!

Powder coating and silk screening are popular because they allow various patterns and logos to be printed on each bottle without significantly altering the manufacturing process.

Step 12: Inspection

Finally, we come to inspection—it’s not just any regular inspection! This one involves inspecting every single item by hand because each product has been checked so often during earlier steps that even if there were any mistakes left over from previous processes, we would have noticed them already!

Step 13: Packing

Once the bottles are made, they are packed into boxes and shipped to a warehouse. From there, they are shipped out to customers all over the world.

Your bottle may undergo a series of tests to ensure it meets quality standards before packing and shipping out! Once you receive your new Hydro Flask water bottle, it’s time to fill up with icy cold beverages, head outside for some adventure, and enjoy life!

What Is Plastic Used to Make Hydro Flask Lids?

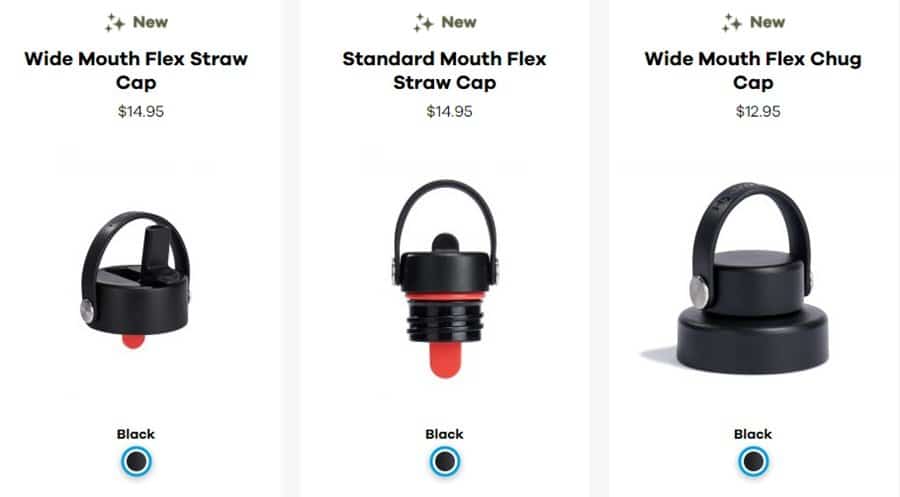

Two main types of Hydro Flask lids are the flip lid and the standard screw top lid.

Both Hydro Flask lids are made from BPA-free plastic that meets FDA requirements for food contact applications. The specific type of plastic used is polypropylene, five # plastic.

This plastic has been recognized and approved by the FDA. It has been adopted to make containers suitable for directly contacting food in various consumer products, such as food storage containers, beverage bottles, and mugs.

Why Powder Coating on Hydro Flask?

The powder coating process applies a hard, scratch-resistant, and durable layer to the exterior of Hydro Flask bottles. It’s used to protect metal surfaces. The technology combines dry powder paint with a binder in an oven. This creates an even finish that protects the metal from wear and tear while maintaining its original color.

Why Hydro Flask Double Walled? What’s Between The Walls?

The walls of the Hydro Flask are made from stainless steel, one of the best materials for keeping your beverages hot or cold. Stainless steel is durable enough for everyday use and doesn’t transfer heat much as other metals.

At the same time, Hydro Flask has developed TempShield double-wall technology to make sure its bottles are entirely vacuum-sealed, so you don’t have to worry about them leaking or being compromised in any way. This vacuum’s creation makes Hydro Flask double-walled bottles effective at keeping their contents at desired temperatures.

Conclusion

So, there you have it! Hopefully, we’ve helped you understand what makes a Hydro Flask tremendous and why they’re so much better than other water bottles. We know there are plenty of other water bottles out there, so if you’re still unsure whether or not to buy one, check out our article on choosing the right reusable water bottle for your needs.